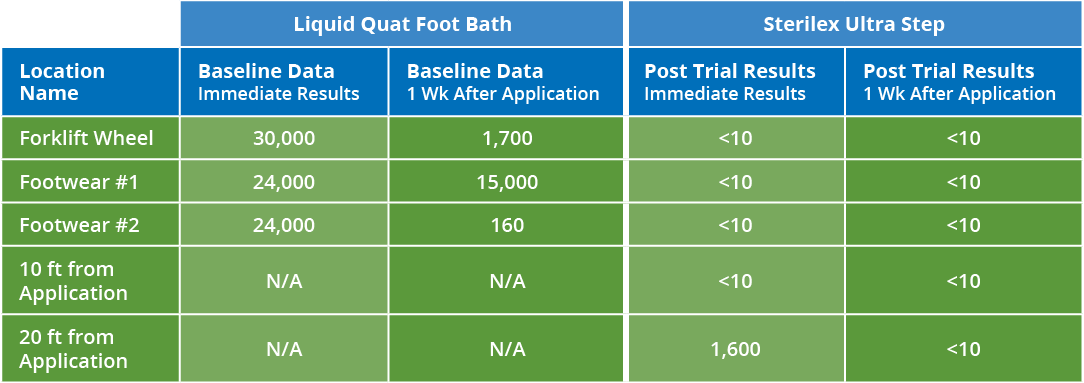

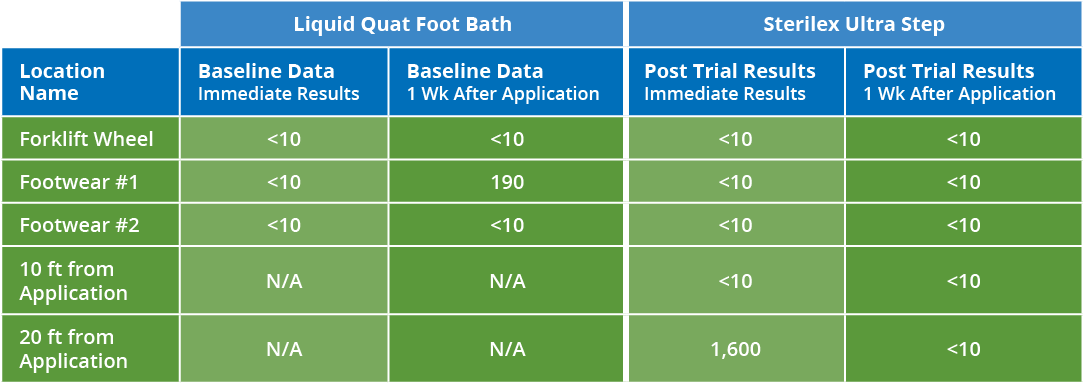

Production floors are the largest vector for cross-contamination. Disinfecting floors during production allows plants to reduce the microbial load going into sanitation and turn lines more quickly. Read on to see before and after pictures from a coffee plant that used Sterilex PerQuat® technology to reduce their pathogen positives.

Following up with Sterilex dry sanitizers not only adds traction and helps prevent slippage, but adds an addition layer of protection against cross-contamination. Additionally, Sterilex Ultra Step and ProvaStride can be used in environments, such as the plant in this case study, where moisture is a concern, and don’t miss our white paper, examining the impact of dry sanitizer and doorway interventions on traction.