Biofilm. Many of us have heard of it but struggle to accurately define and understand.

Biofilms cost the U.S. billions of dollars every year in energy losses, equipment damage, product contamination and medical infections. Biofilms are considered a public health threat because of their outstanding resistance to antibacterial treatments and disinfection.

Biofilm is a grouping of cells that stick together, embedded in a self-produced matrix of extracellular polymeric substance (EPS) composed of proteins, polysaccharides and other materials. More simply, the biofilm provides a protective home that helps pathogens resist disinfection. Before learning how to effectively remove biofilm, we first must understand how it’s formed.

Extracellular Polymeric Substance (EPS)

The extracellular polymeric substance (EPS) is composed of a complex mixture of proteins, lipids, nucleic acids, and polysaccharides. EPS is a long, sugary molecular strand that not only attaches biofilm to a surface, but also traps nutrients, provides structural support and protects microbes from antimicrobial treatments and disinfectants.

Most biofilms are too thin to see with the naked eye, just a few cell layers thick. There are several different environmental factors that directly impact the thickness of biofilm. Biofilms form more readily in warm, stagnant water. Water flow, or the stress from the flow of water, is an important factor that can slow the growth of biofilm. Additionally, organism type can impact biofilm production. Some organisms produce large amounts of EPS and therefore grow a thicker biofilm.

How biofilm is formed

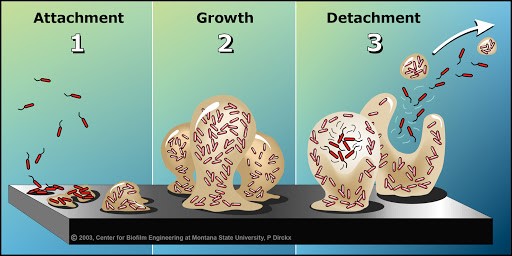

Biofilm formation commonly occurs in three main stages:

- Attachment: Single free-floating bacteria land on surfaces and bacterial cells aggregate and attach to one another. Pathogens know they have the best chance of survival as part of a community, or biofilm. Bacteria excrete a slimy, glue-like substance which allow biofilms to form and cling to nearly any damp surface.

- Growth: Cells begin producing EPS and are held together by these strands developing resilient, three-dimensional microcolonies that become irreversibly attached. This complex structure is packed with water channels that facilitate the exchange of nutrients and waste products.

- Detachment/Dispersal: Biofilm spreads by detaching small or large clumps of cells, or by a type of “seeding dispersal” that releases individual cells allowing the bacteria to attach to a surface or biofilm downstream. Think of the release of seeds from a dandelion, this is a similar process of encouraging species growth.

Biofilm Resistance

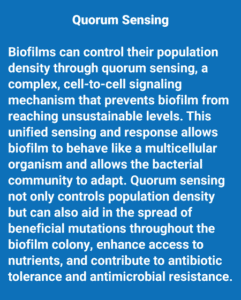

The EPS acts as the first line of defense against factors such as lack of water, high or low pH, or the presence of antibiotics or antimicrobials. Research has shown that bacteria in biofilm are often 1,000 times more tolerant to antimicrobial treatment than their planktonic (free floating) counterparts due to different mechanisms. Biofilm protects pathogens from disinfection and allows organisms injured by environmental stress and disinfectants to recover and grow, which can lead to improved resistance to antimicrobials and antibiotics over time as ‘stronger’ organisms continue to survive. It is imperative to completely remove biofilm to avoid continued resistance.

Protection against biofilm

The best way to protect against biofilm is prevent its formation. Simply killing free-swimming and surface level biofilm-related microorganisms, without removing the biofilm structure from a surface, can result in rapid recolonization of organisms from inside the remaining biofilm matrix. Conventional disinfectants have limited effectiveness against biofilm without extensive manual removal like scrubbing, making it imperative to choose a disinfectant that’s label specifically states it is proven to both remove biofilm and kill bacteria.

Sterilex’s patented PerQuat technology was the first chemistry to receive EPA-registered anti-biofilm claims for industrial and public health use sites, including animal drinking lines. It has the unique ability to collapse the protective matrix, penetrate the biofilm, kill pathogenic microorganisms, dissolve the biofilm structure, and chemically scrub the structure from a surface. Dissolving the biofilm structure and fully removing it from a surface is a proactive approach in preventing the repopulation of biofilm matrix and microbial contamination.

Clean, uncontaminated water directly impacts flock health and performance. FortiSolve provides efficacy against slime forming bacteria in poultry waterlines and kills and inactivates organisms and viruses such as Salmonella, E.coli, Avian Influenza and other poultry and swine pathogens.