In most processing and environmental facilities, biofilm lurks as a hidden menace hiding in areas that are tough to reach and harboring dangerous pathogens that can be a cross-contamination risk. If we look deeper into the life cycle of the bacteria within a biofilm, we find another layer of hidden peril, seeding dispersal.

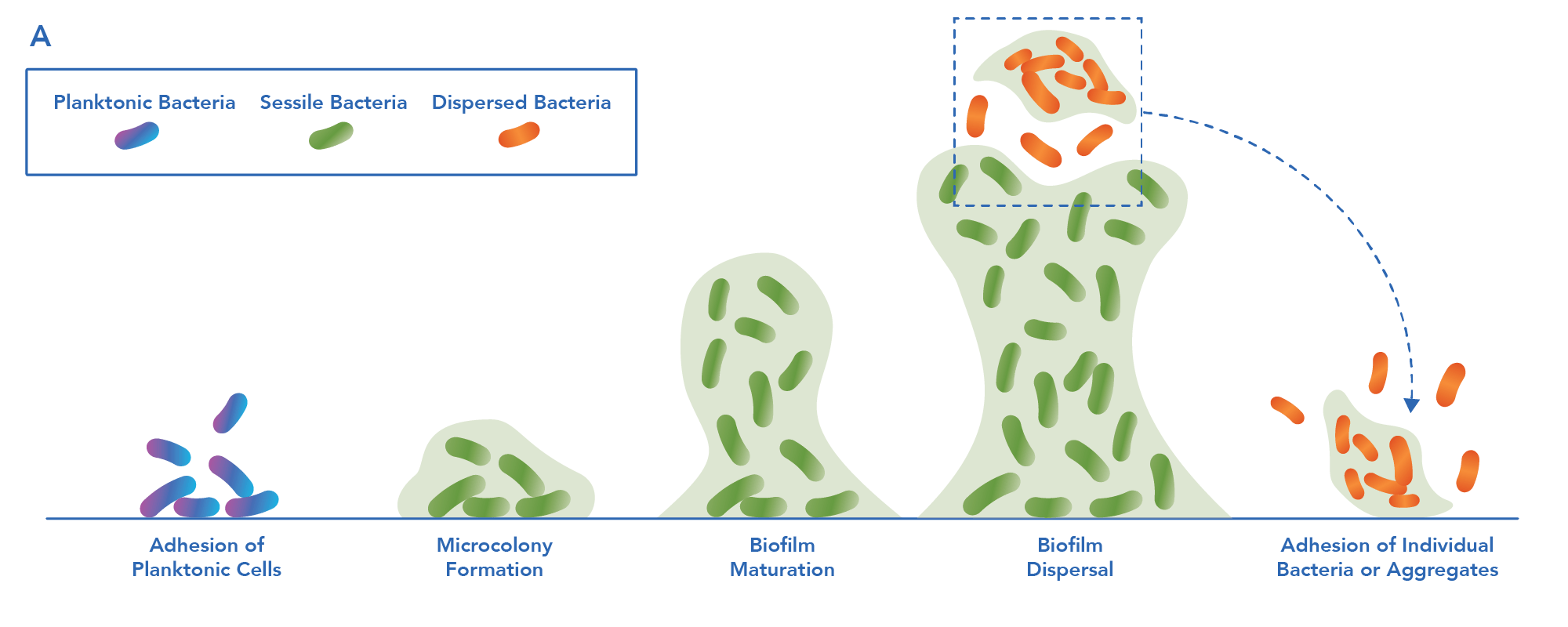

In our first Biofilm Basics insight, we explored how biofilm is formed by free-floating organisms that can attach to surfaces and start to form biofilm. Biofilm is constructed of an extracellular polymeric substance (EPS), a matrix of polysaccharides, lipids and proteins (López, 2010). These organisms have two sources: introduction to the system externally (system inputs) or from somewhere else inside the system after releasing from an already formed biofilm. Biofilms are left behind from improper cleaning and removal. This process is called seeding dispersal.

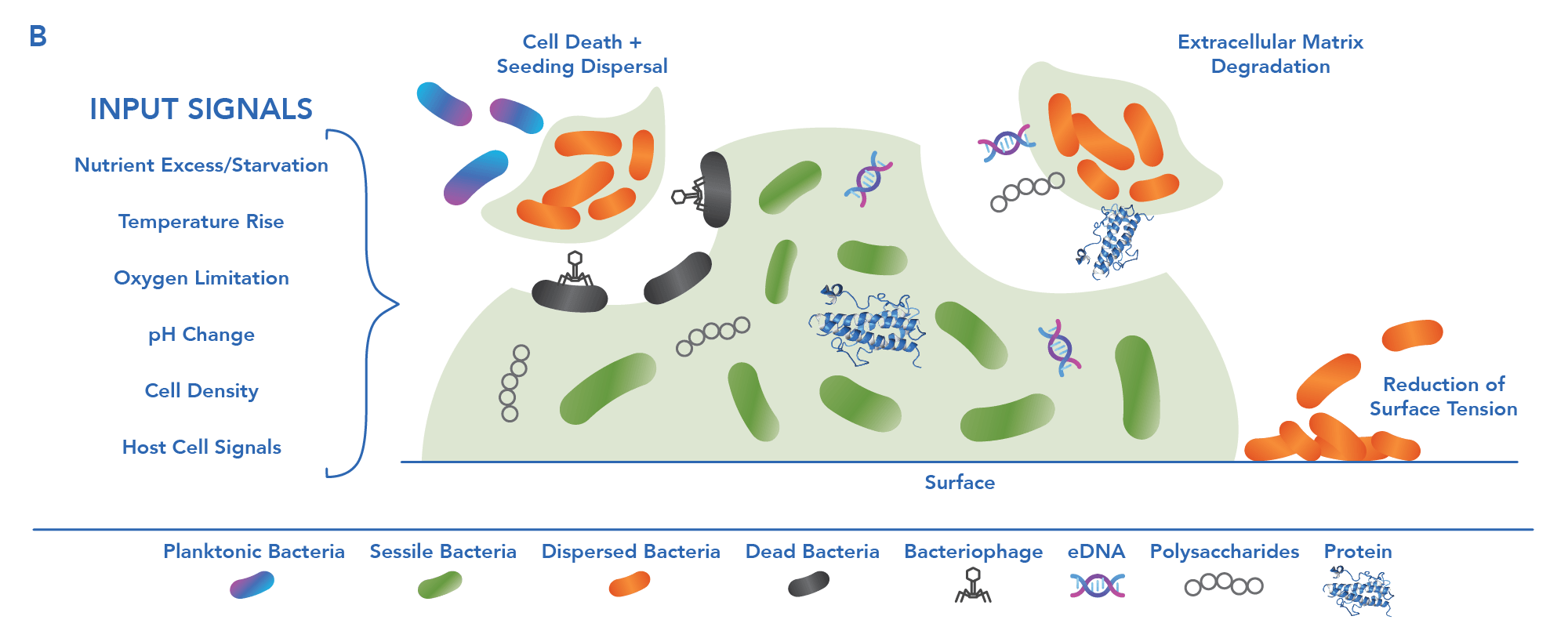

There are a wide variety of factors that can initiate seeding dispersal. True to the complexity of life, it has been shown that environmental factors ranging from a lack or overabundance of nutrients, to temperature changes, to changes in pH or oxygen levels can initiate dispersion mechanisms (Guilhen, 2017).

Once the dispersion signal is received by the bacteria, the bacteria will release itself from the biofilm through several mechanisms: either the degradation of the EPS matrix itself through secreted enzymes or through cellular changes like surface tension reduction or cell structure disruption. (Guilhen, 2017). Now the bacteria are free-floating and able to reattach to other surfaces.

To understand the full contamination implications seeding dispersal can have on food production surfaces, it is helpful to picture what it looks like in a real-world example. In a simple, fluid milk circuit, bacteria naturally found in raw milk will constantly inoculate the system and produce biofilm in all the equipment at least up to the pasteurizer. If biofilm is not fully removed and dangerous pathogens not destroyed during the sanitation process, established large colonies of bacteria in the system will eventually receive the dispersal signal and will be released during production. Thermophiles and spore-forming bacteria can survive the pasteurization process and re-establish biofilms further down the processing chain into the homogenization step or even final packaging. (Delgado, 2013). This is a serious human health risk.

At Sterilex, we pride ourselves on being experts in understanding how biofilm works and the risks biofilm poses to food processing and other environments. Our PerQuat® Technology is the most complete biofilm control solution on the market. Sterilex PerQuat products were the first products on the market that are EPA registered to both remove public health biofilms and kill pathogens in biofilm. Continued use of Sterilex’s PerQuat products can help ensure your system is fully clean by controlling biofilm, seeding dispersal and system seeding.

Sources:

Lopez, D., Vlamakis, H., & Kolter, R. (2010). Biofilms. Cold Spring Harbor Perspectives in Biology, 2(7). doi:10.1101/cshperspect.a000398

Guilhen, C., Forestier, C., & Balestrino, D. (2017). Biofilm dispersal: Multiple elaborate strategies for dissemination of bacteria with unique properties. Molecular Microbiology, 105(2), 188-210. doi:10.1111/mmi.13698

Delgado, S., Rachid, C. T., Fernández, E., Rychlik, T., Alegría, Á, Peixoto, R. S., & Mayo, B. (2013). Diversity of thermophilic bacteria in raw, pasteurized and selectively-cultured milk, as assessed by culturing, PCR-DGGE and pyrosequencing. Food Microbiology, 36(1), 103-111. doi:10.1016/j.fm.2013.04.015